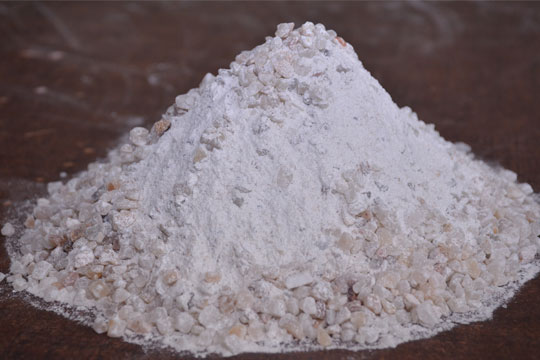

About Acidic Ramming Mass

Silica ramming mass is also known as Acidic Ramming Mass, is used in steel Induction furnaces, for the purpose melting of iron scrap and sponge iron. We provide quality silica ramming mass which helps in achieving the temperature up to 1710°C. They are used in the Lining of induction furnaces.

Normally, the selection of refractory for the furnace lining is based on the type of slag generated during melting. There are three types of ramming masses namely (i) acidic, (ii) basic, and (iii) neutral.

The most commonly used lining material for an induction furnace is acidic lining. It normally consists of high purity silica ramming mass. Silica ramming mass is used for melting carbon steels with carbon content higher than 0.1 %. The purity of quartzite is important since the impurities present produces unpredictable and higher amounts of liquid phase at high temperatures. High purity silica Ramming mass yields more lining life.

The Acidic Ramming Mss is manufactured under the supervision of our qualified & experienced workforce. Manufacturing is overseen such that iron free material is produced and there is proper composition of granules according to the furnace requirements. Ramming mass should have thermal stability, must be resistant to corrosion and moisture free. Better quality of lining results in the smooth functioning of the furnaces.

Grades of Acidic Ramming Mass

- Ordinary Grade- It is mainly used in small induction furnaces. Recommended up to 1600°C. They are used in the Lining of induction furnaces. Ramming mass should have thermal stability, must be resistant to corrosion and moisture free. Better quality of lining results in the smooth functioning of the furnaces.

- Super white/Premium- It is mainly used in higher capacity induction furnaces for better resistance to high temperature. Recommended up to 1710°C. It shows 15-20% better results as compared to other ramming masses. It is also suitable for continuous casting mills (CCM Industries). It helps in reducing energy consumption and time. Many large steel plants prefer to use Super white grade due to its qualities.

- Pre-mixed- This product is the best quality ramming mass which has optimum performance at high temperatures. It is Ready-To-Use material without moisture content. It is mixed with boric acid and packed in moisture proof liner bags. Many steel industries prefer this ready-To-Use material to save time used in mixing Boric acid in every patching and also it saves space and labour charges. Best quality and pure Boric Acid is used to give best results. Correct quantity of Boric acid is properly mixed in a mixer as per the customer’s need depending on furnace type and size to achieve maximum number of heats (turnings) in each patching which helps by reducing the cost of production for the end user (manufacturer).

- Nali Top- Made of quartz, specially made for Nali top area of the furnaces. Due to its cheaper price, the production cost of steel is slightly reduced and this is why it is quite popular. Moreover, Nali Top areas of steel plants don't require Premium grade Ramming Mass.

Specification

a) Chemical Composition

| Silica | SiO2 | 98 to 99% |

| Alumina | Al2O3 | 0.04% |

| Ferric Oxide | Fe2O3 | 0.04-0.06% |

| Manganese Oxide | MnO | Nil |

| Calcium Oxide | CaO | Nil |

| Magnesium Oxide | MgO | Nil |

| Sodium Oxide | Na2O | 0.05% |

| Potassium Oxide | K2O | Nil |

| Loss in Ignition | - | 0.08% |

| Sintering Temp. | 1200°C | |

| Max Service Temp. | 1710°C | |

| Grain Sizes | 0 to 5 mm |

b) Product features

| Ramming Mass Grades | Max temp | Max grain | Grain silica | Fe2O3 |

| Premium silica ramming mass | 1710°C | 5 mm | 99% | 0.05% |

| Ordinary grade | 1600°C | 6-7 mm | 98% | 0.07% |

| Nalitop | 1500°C | 6-7 mm | 97% | 0.3% |

| Pre-Mix Silica Ramming Mass | 1710°C | 5 mm | 99% | 0.04% |

c) Salient Features

- Product is good and stable at high furnace temperatures

- Free of iron oxide (FeO)

- Electrical resistivity helps prevent shot circuiting

- Suitable upto 1710°C

- Grain-sizes and percentage as per customer requirements

- Silica percentage (above 98.65%)

- Moisture free and strong packaging

- Higher density and strength of the lining

Application of Products

- SS Steel

- Alloy Steels

- Cast Irons

- Ingot Iron

- Iron Billets

- Alloy cast iron

Manufacturing Process

Big materials are fed to the jaw crusher evenly and gradually and sent to the hopper as a primary crushing. After first crush, the material will be transferred to impact crusher by belt conveyer for secondary crush, the crushed materials will then be transferred to vibrating screen for separation. After separating it is passed through strong magnets to remove if or any iron particles from the quartz powder& grains. Then acidic ramming mass is produced by mixing various quartz material at different percentage to prepare Acidic Ramming Mass. In Pre-Mix Ramming Mass, Boric Acid is also added in above mixture for ready to use lining material.

Packaging

- HDPE Bags New & Old Bags

- HDPE Bags with inner lining for moisture proofing

- PP Bags Printed & Plain

Primary Competitive Advantage/USP-

- Experienced R&D Development

- Large production capacity

- Good financial position

- Provide customised solutions

- Testing of products done before selling

- Samples provided to customers

- Feedback of product performance

- Preferential pricing for End User

Target Market- Iron and Steel Industries in

- Rajasthan

- Uttar Pradesh

- Uttarakhand

- Chhattisgarh

- Bihar

- Maharashtra

- Gujarat

- Various Union territories (UTIs)

- Overseas Market like GCC Countries, Africa, Far East & Neighbouring countries